BACK TO BASICS

By Janna Hamlett, Ph.D.

Handling Customer Complaints in Food Manufacturing

Although customer complaints can be viewed as a negative, managing them is an important risk management strategy

SCROLL DOWN

Photo credit: richyrichimages/E+ via Getty Images

People who work in the food industry can readily swap stories of those customers—the ones who are never satisfied, no matter what actions are taken to appease them. Some people, it is said, just like to complain. According to the 2020 National Customer Rage Survey, for every one reported complaint, there may be an additional 25 unreported complaints.1 Another statistic from that survey found that dissatisfied customers will tell an average of seven people when they have a negative experience, but will tell only 3.7 people when they have a satisfying experience.1

Although handling customer complaints may not be the most enjoyable experience, it is very important. Complaints can be very detrimental to a business; however, if handled properly, they can also result in positive outcomes.

Unfortunately, customer complaints can lead to a loss of sales and a reduction in customer confidence. New customers may have read or heard about a company's reputation via other customer complaints and comments; consequently, instead of purchasing one company's product, they purchase a product from a competing company. If a business does not handle current customer comments well, it could lose repeat orders and its status as the preferred vendor in its supply chain program. An estimated $494 billion in revenue is lost because of poor handling of customer complaints.2 In addition, customer complaints can result in recalls or additional regulatory scrutiny.

Whether a company sells direct to consumers or to other manufacturers, customer complaints must be monitored and responded to quickly. Of course, some customer complaints are just "nuisance complaints"—coming from people who are trying to get manufacturer credit or free product; however, even those types of complaints should be noted and documented. Hidden in those complaints is valuable information for both the product and company. Bill Gates, Microsoft founder, once said, "Your most unhappy customers are your greatest source of learning." Customer complaints can be valuable to the research and development process. The voice of the customer helps determine the critical to quality attributes; what better way of getting that data than from actual customers? If a customer complaint is handled well, it may actually improve the relationship with that customer by allowing them to feel that they are vital to the company and to the quality of its products.

The culture of a facility in food safety or customer relations is also impacted by how customer communications are managed. Customer complaint trending and response are part of a risk management strategy. The objective of any management system is to try to protect the company from adverse actions. Understanding and responding to customer complaints is one strategy.

In addition, regulatory and third-party auditing companies require companies to have a customer complaint or customer relation protocol. Global Food Safety Initiative (GFSI)-approved scheme owners have a requirement for managing customer communications. For example, Safe Quality Foods (SQF) Edition 9, in "2.1.3: Complaint Management," requires the following:

- 2.1.3.1: The methods and responsibility for handling, investigating, and resolving food safety complaints from commercial customers, consumers, and authorities, arising from products manufactured or handled on-site or co-manufactured, shall be documented and implemented.

- 2.1.3.2: Adverse trends of customer complaint data shall be investigated and analyzed, and the root cause established by personnel knowledgeable about the incidents."3

The code then outlines the requirements for corrective and preventive action and root cause analysis.

"Since customers can leave comments in many ways, a company must have a way of collecting this data from those diverse methods. "

Contact Information

It is important that customers have a way to reach a business. The U.S. Food and Drug Administration requires the name and place of business to appear on the label of every food product, usually in the principal display panel (PDP). However, it is important to ensure that customers have a way of contacting the business directly.

In addition, it is important to keep in mind that customer feedback does not always come through designated customer support channels. Feedback will appear in online forums, on social media, in online marketplaces, and in online rating apps. These channels should be monitored so that customer feedback and complaints appearing there can be noted and managed.

Complaint Management

It is important to ensure that the system or person in charge of initially taking the complaint is trained to know what questions to ask and what information to gather. The person or system who takes the complaint must gather as much information as possible. If a staff member is taking the information, a list of questions or a template should be provided so that the staff can ask probing questions of the customer. If a web system or form is in place to allow customers to enter their information, ensure that a variety of questions are listed on the form to gather as much information as possible from the customer. This information will be vital for the investigation and root cause determination. Whenever a customer can provide pictures or samples of a faulty product, it will provide additional helpful information for the investigators.

Since customers can leave comments in many ways, a company must have a way of collecting this data from those diverse methods. Someone in the company must have, as part of their position description, the responsibility for managing customer complaints. If no one owns this process as part of their job duties, then it runs the risk of being overlooked. Depending on a company's size, customer complaint investigations, trending, and responses may be included as a portion of the responsibilities of several departments.

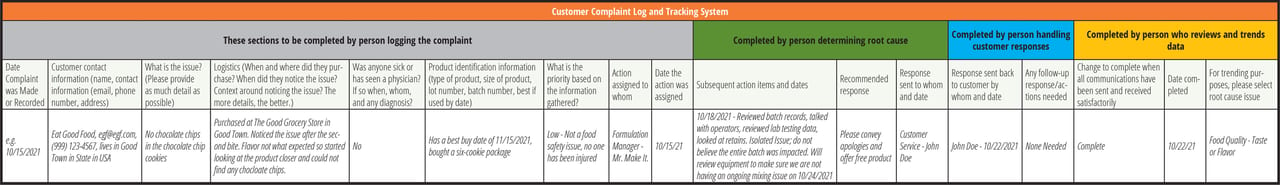

A central database or customer relationship management (CRM) program is a necessity. Many commercial CRM programs are available. A company must determine what elements best fit its business model and culture before selecting a CRM. However, a simple Excel sheet can be used to start (Figure 1) and be modified as needed.

FIGURE 1. Customer Complaint Document Template

Complaint Classification Systems

A complaint management program must have some definition of classification and speed of follow-up. Many CRM programs have reports that search for key words and then trigger a notification to an authorized person. However, if the CRM does not have an automated system, ensure that the person(s) reviewing complaints understands the classification system. Obviously, a food safety complaint that may initiate a recall requires immediate attention. However, a complaint about the texture of a product should not be ignored, either. Quality complaints are important for critical to quality assessment and are an excellent data tool for the voice of the customer, although they may not need to be reviewed and investigated immediately.

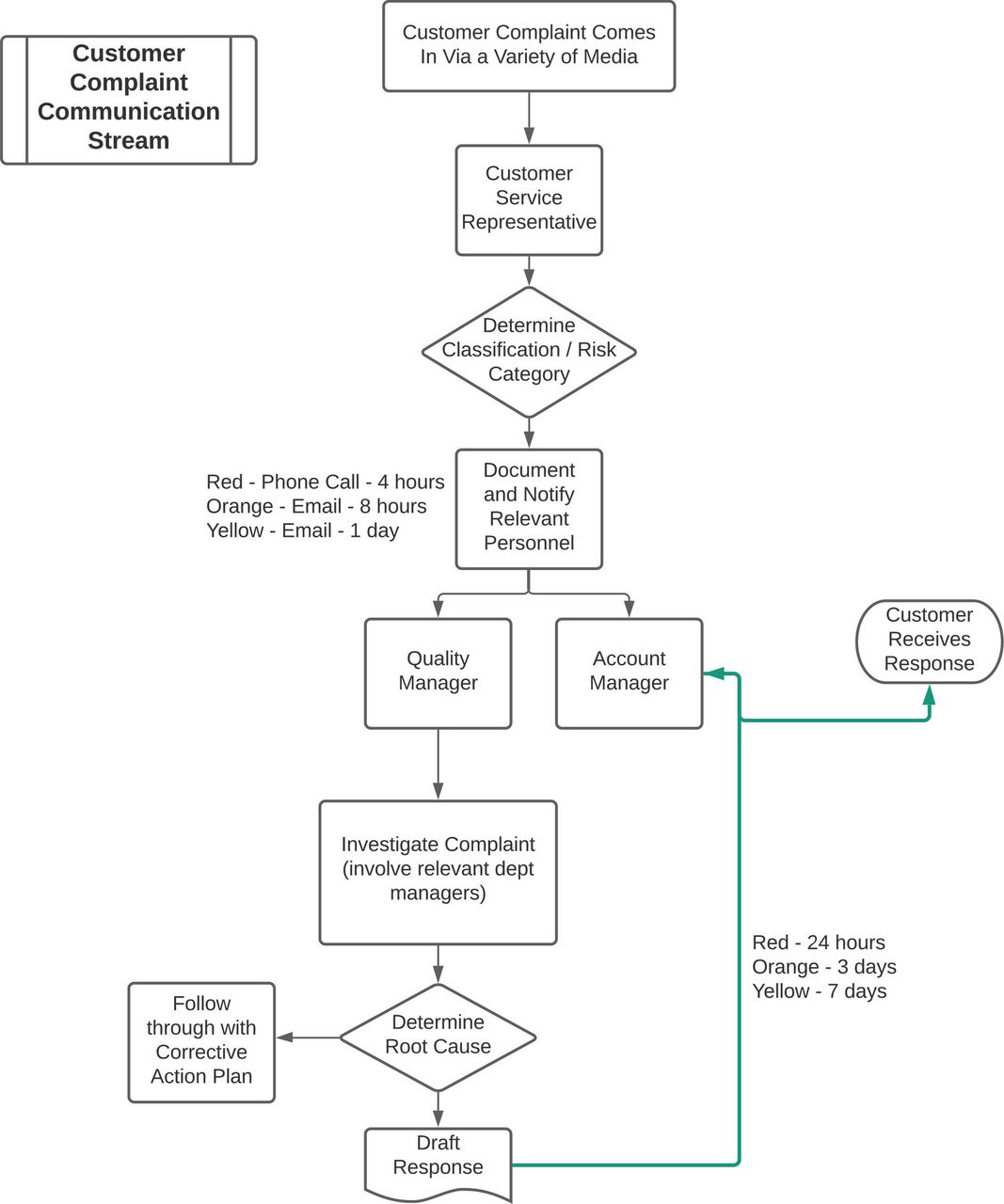

Some companies classify complaints in a high, medium, or low classification, or by color: red, orange, yellow, etc. However complaints are classified, a complaint prioritization system is needed. Once complaints are prioritized, they must be followed up with according to the policy. For example, the high-risk/"red" food safety complaints should be addressed within 24 hours, the medium-risk/"orange" complaints should be answered within three days, and then low-risk/"yellow" complaints should be addressed within seven days.

Communication Streams for Handling Complaints

A customer complaint management program should have a flowchart of who will receive the complaint in what timeframe. Some CRM systems have features that will send information automatically to emails or cell phones, and if responses are not made within a certain time frame, then the CRM will automatically escalate the information up the organization chart. However, communication streams should be created within each organization to ensure timely responses. Figure 2 shows an example of a communication flowchart with generic department headings. Actual job titles and/or employee names should be included to ensure that the flowchart meets a company's needs and staffing.

Establishing a clear method for specific communication streams will help ensure that no complaint is lost or forgotten. Remember, handling customer complaints can also lead to a positive outcome, but it is essential to communicate back to those customers so that they know their feedback has been received and acted on.

FIGURE 2. Customer Complaint Communication Stream

Trending for Improvement Strategies

It is also important to develop a policy for how often customer complaints are reviewed and trended. For example, all complaints can be trended once per quarter to identify the most frequent complaints that the team can analyze and review. This can be viewed as a product development possibility and a continuous improvement strategy. Those trends should be integrated as part of the management review process for the company's food safety and operational strategies. Statistical process controls tools should be used, and the data should be trended so that it is apparent when improvements are being made or when ground is being lost.

Some examples for data trending on complaints that may be useful include:

- Classifying the total number of complaints

- Classifying complaints per X number of shipments

- Classifying complaints per X pounds of product

- Classifying complaints by topic/root cause.

This data can be used to create a baseline for improvement targets using SMART (specific, measurable, attainable, relevant, time-based) goals. Regular review of those trends guards against complacency.

Communication and Training Event

Customer complaints should not remain only within the quality or sales department. Customer complaint data and subsequent investigations can be used to communicate to operations and staff. Communicating what the customer is experiencing with the product is an excellent source of training material and a catalyst for impactful communication with operators and staff. Part of having a positive food safety culture is empowering employees of all levels in the organization with information and making them feel that their opinions and ideas are important. It is important to involve operators in the root cause analysis and response.

Getting the Most Out of Customer Complaints

Although customer complaints can be viewed as a nuisance or a less desirable part of the company workload, the management of such complaints is an important risk management strategy. It is essential to establish a program to capture, respond, and trend customer complaints to gather the most information possible. Rather than being viewed as a negative occurrence, customer complaints can be used to train and communicate with current staff and as a valuable data point for critical to quality assessments. If handled well, they can also be turned into a positive interaction with a customer.

References

- Customer Care Measurement & Consulting. "2020 National Customer Rage Study." https://www.customercaremc.com/insights/national-customer-rage-study/2020-national-customer-rage-study/.

- Farnsworth, Derek, Jennifer L. Clark, Allen Wysocki, Karl Kepner, and Michelle Glassner. "Customer Complaints and Types of Customers." University of Florida Extension: AskIFAS. https://edis.ifas.ufl.edu/publication/HR005.

- "Food Safety Code: Food Manufacturing, Edition 9." Safe Quality Foods Institute. https://www.sqfi.com/.

Janna Hamlett, Ph.D., is an Assistant Professor at the University of Idaho Extension and a Food Processing Specialist with TechHelp, Idaho's Manufacturing Extension Partnership Center. She has over 15 years of experience in the food manufacturing industry, with a background in quality and operations management including numerous certifications in lean processing management, personnel safety, and food safety and quality programs.