Check-Set Thermometer System Supports Regulatory Compliance, Traceability

Tel-Tru Temperature Solutions: +1 800-232-5335

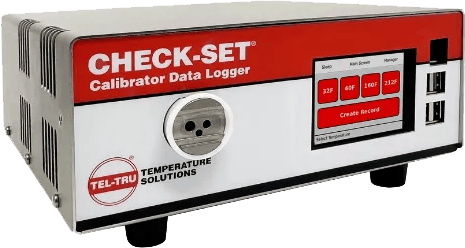

Tel-Tru Temperature Solutions has introduced its Check-Set Thermometer Calibrator Data Logger and Check-Set Thermometer Calibrator designed for the food and beverage industries. Check-Set delivers lab-grade temperature calibration accuracy to ±0.2 °F (0.1 °C) without traditional boiling water and ice bath methods, offering a faster and more reliable solution for food safety and quality teams. The Check-Set Data Logger also eliminates manual recordkeeping vulnerabilities by providing secure, traceable digital records.

SCROLL

DOWN

With automatic calibration reminders, manager lockout on expired certificates, and data export in .CSV format, the Check-Set Data Logger ensures that every calibration is documented, defensible, and compliant with U.S. Food and Drug Administration (FDA) Food Safety Modernization Act (FSMA), Global Food Safety Initiative (GFSI), and Hazard Analysis and Critical Control Points (HACCP) requirements.

SkillUp Training Solution for Food Manufacturers

Registrar Corp contact form

Registrar Corp has launched SkillUp, a complete workforce training solution for food manufacturing. Food manufacturers face unique challenges, which contribute to workforce turnover that is more than double the U.S. average. Such challenges include high-risk injury potential, safeguarding against foodborne illnesses, highly unique working conditions, multi-lingual workforces, routine audits, and other factors.

Registrar Corp's newest training solution, SkillUp, bridges the gap with an industry-specific training platform specifically designed for easy implementation within food manufacturing facilities and throughout the industry. SkillUp provides scenario-based training content, using real-world situations commonly encountered in food and beverage production. The platform prioritizes short e-learning modules with interactive exercises to ensure greater comprehension and recall, helping to seamlessly implement learnings within organizations.

Water-Saving, High-Speed Packaging Technologies

Heat and Control contact page

Heat and Control has introduced two innovations designed to meet industry's evolving demands for sustainability and efficiency: the Cascade Water Recirculation system and the Inspira Series high-speed bagmaker. The Cascade Water Recirculation system is engineered to help food processors reduce freshwater consumption by up to 75 percent, without compromising product integrity or equipment reliability. This solution integrates two specialized modules, the Slice Wash Support Module (SWSM) and the Process Recirculation Support Module (PRSM). Together, these components deliver significant reductions in freshwater and energy usage, enhanced process performance, and improved sanitation outcomes.

Eriez Launches SenseGuard X-Ray Series

Eriez contact page

Eriez has announced the launch of its SenseGuard X-ray Inspection Systems, developed to support product safety, regulatory compliance, and quality assurance across processing environments. The SenseGuard line integrates high-definition imaging with artificial intelligence (AI) analysis to identify a range of physical contaminants, including metal, glass, stone, bone, and dense plastics. In addition to contaminant detection, the systems can assess fill levels, seal integrity, and the presence of required components.

The product line includes four series, each designed for specific inspection applications: the XRP Series, for packaged goods; the XRB Series, for raw, unpackaged bulk materials; the XRS Series, for upright containers; and the XRL Series, for liquid and semi-solid pipeline products.

Drainage Design Solution for Newbuild Food Facilities

FoodSafe Drains: info@foodsafedrains.com or +1 855-497-7508

FoodSafe Drains has launched Envision, a suite of products, services, and solutions designed specifically for new construction projects in the food and beverage manufacturing and processing industry. Envision delivers an integrated approach, leveraging FoodSafe Drains' design-build expertise and a nationwide network of Alliance Partners to provide tailored support for facility owners, engineers, architects, general contractors, and construction managers.

Envision streamlines the complexities of new food and beverage facility construction by offering both standardized, in-stock drainage solutions and custom-designed products. Facility managers, project managers, architects, and engineers can feel confident in their drainage solution design and specification efforts with Envision's design-assist support, drain layout development, product selection guidance, technical consultation, and budget assessments.

New Software Aims to Ease UK Food Safety Inspection Backlog

Grape Software contact form

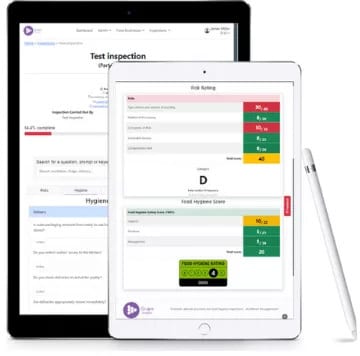

Grape Software has announced the release of a new food hygiene inspection software for UK Local Authorities, designed to simplify the inspection process and help reduce the growing backlog of food businesses currently awaiting an inspection. According to the UK Food Standards Agency (FSA), as of June 2025, an estimated 95,000 food businesses are overdue for hygiene inspections, including 841 classified as "high risk."

Designed to address this pain point, Grape INSPECT was purpose-built for Environmental Health Officers across the UK. The software replaces outdated paper-based practices and digitizes the entire inspection process, allowing decisions on food hygiene ratings to be made and published within days rather than weeks. Users can record and upload notes and photographs during inspections, directly onsite. The system then generates the inspection report with a food hygiene rating, with all information being stored securely and easily accessible. Grape Software collaborated with Environmental Health Officers to develop Grape INSPECT, ensuring the technology is not only efficient, but also user-friendly.

Transmitters for Non-Contact Measurement of Solids, Liquids in Silos, Tanks

KROHNE contact form

KROHNE has introduced the OPTIWAVE 1530 and OPTIWAVE 1560 radar Frequency Modulated Continuous Wave (FMCW) level transmitters to deliver accurate, non-contact measurement of solids and liquids. The OPTIWAVE 1530 provides a cost-effective solution with a measuring range of 0–15 meters (m) or 49.2 feet (ft.), making it well-suited for small to medium silos, stockpiles, bunkers, and tanks. The OPTIWAVE 1560 extends this capability to 30 m (98.4 ft.) for long-range measurement in tall silos, large tanks, and deep vessels. Both models deliver drift-free, maintenance-free operation without the need for recalibration over the lifetime of the product, significantly reducing total cost of ownership.

Built for durability, both models feature a compact, robust design with fully potted electronics to protect internal components from dust, condensation, vibration, and shocks. The flush-mounted, concave PVDF lens antenna offers excellent chemical resistance and a self-draining design to prevent buildup, maintain a stable radar signal, and ensure consistent performance, even with condensation present. With a narrow 4-degree beam angle, these transmitters achieve exceptional accuracy in tight spaces and in vessels with internal obstructions by avoiding interference from walls or fixtures.

Chemical Analysis Platform Enables Microplastics Detection in Food

StellarNet: ContactUs@StellarNet.us

StellarNet has introduced the enhanced StellarScope AM/PA, a chemical analysis platform that combines automated mapping and particle analysis in a single system. It unites micron-scale morphological imaging with Raman spectroscopy, all driven by intelligent software control. Built for high-precision material characterization, the system empowers users to detect, measure, classify, and chemically identify microscopic particles across diverse applications.

With the ability to identify particles as small as 1 micron, StellarScope AM/PA helps the food industry detect contaminants in real time, before they reach consumers. The technology, which was enhanced in 2025 with next-generation automapping, is already in use by food and ingredient manufacturers.

Touchless Traceability for Food Industry

Distribution Centers

ReposiTrak contact form

ReposiTrak has introduced a Touchless Traceability solution designed specifically for distribution centers (DCs). The traceability solution addresses a longstanding operational challenge: the ability to easily capture and share lot codes and related shipping data for all items shipped to customers. The solution enables retailers and wholesalers operating DCs to meet regulatory and customer-driven traceability requirements with no added labor, no label scanning, and no need for an expensive overhaul of existing Warehouse Management System (WMS) platforms.

Case- or item-level scanning at the DC would dramatically increase labor, decrease throughput, and introduce new risks. Scanning at the store or restaurant level to confirm lot codes shipped and received would pose additional challenges, especially in operations where deliveries are large or if deliveries occur during off-hours. ReposiTrak's solution eliminates the need for scanning by automatically linking existing supplier data to data from the DC's systems.

Predictive Monitoring Tool for Dairy, Beverage Production

GEA contact form

GEA has introduced GEA InsightPartner EvoHDry, a digital condition monitoring tool developed to support operational reliability in dairy and beverage production environments. The system is designed for facilities producing items such as infant formula, cream, evaporated milk, condensed milk, and cheese, where consistent performance is critical.

The tool applies real-time monitoring to track parameters including temperature, pressure, vibration, and flow. This data-driven approach enables early detection of equipment degradation, helping operators identify issues such as suction pressure loss in vacuum pumps—one of the leading causes of unplanned downtime in evaporation systems. Predictive analytics generate pre-alarm notifications, allowing for timely intervention before failures occur. The solution is tailored for use with evaporators, spray dryers, pumps, and rotating equipment, and extends monitoring through cleaning cycles.

New and Improved Pipeline X-Ray System

Eagle Product Inspection contact

Eagle Product Inspection recently unveiled its redesigned Pipeline X-Ray System for pumped products, offering improved machine construction and built-in inspection technologies. Pipelines uses advanced PXT photon-counting dual energy X-ray technology for bone and foreign metal detection in poultry, meat, pet food, and other pumped products, with the ability to reject items before packaging or further processing with a lower false reject rate. The system offers flexible configurations and has unique features, such as a flowmeter with variable speed functionality, test ball insertion port, and reject catch port. Additionally, users can choose from multiple detection options, including single, dual, and photon-counting PXT technologies. Pipeline's construction also withstands harsh washdown conditions and has been refined to comply with North American Meat Institute (NAMI) guidelines for hygiene and sanitation. The system also fully aligns with the meat and poultry industry's Directives, Regulations, Norms, and Standards (DRNS).