The all-in-one solution includes hardware, an integrated SIM (iSIM), IoT connectivity, and an IoT platform that manages the connection and firmware updates. The Smart Label uses smart motion sensors that detect movement and acceleration, powered by GPS technology that is precise at ranges smaller than 10 meters in ideal conditions. Ultra-thin and only slightly larger than a credit card, the Smart Label is easy to use and simple to deploy, and is coupled with customizable reporting frequencies and agile, cloud-based configurations.

Additional features of the G+D Smart Label include an open-close sensor for tamper protection and automated proof of delivery, and a temperature monitor to ensure the integrity of perishable goods. Label activation is triggered when it is peeled and applied to an item. It is also reusable and certified for air travel.

New Smart Label Solution for Package Tracking and Monitoring

Giesecke+Devrient contact form

The Giesecke+Devrient (G+D) Smart Label is a new tracking solution that can transform any package into an Internet of Things (IoT) device. Developed in collaboration with hardware provider Sensos, the G+D Smart Label enables cost-effective, accurate location tracking for applications like parcel delivery and shipping, fleet management, and monitoring the movement of goods.

SCROLL

DOWN

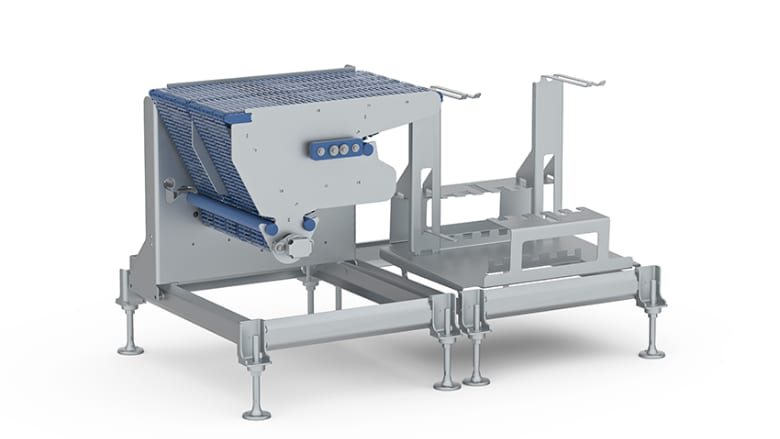

The X5 Pack Curtainless features an incline/decline conveyor design, protective shields, and safety features, helping limit X-ray emissions to levels below regulatory requirements. The system’s baffle plates remove line of sight into the X-ray beam and restrict the aperture height to 85 millimeters (mm), significantly reducing emissions to less than 1 microsievert per hour (μSv/hr) without the need for aluminum filtering.

With its setup wizard, the X5 Pack Curtainless can learn and switch between products within minutes. The latest digital technology from Loma improves image quality, allowing for detection of a wide range of contaminants, including all metal, bone, glass, dense plastics, foil trays, and metalized film. The heavy-duty conveyor components, built for continuous operation, include a passkey-protected setup, an integrated PC with ethernet connectivity, and a front-access USB port. Additionally, to ensure high throughput, the system efficiently handles multi-lane or bulk-flowing food products.

Curtainless X-Ray Inspection System for Lightweight, Unpackaged Foods

Loma Systems: +1 800-872-5662

Loma Systems contact form

Loma Systems recently unveiled its new X5 Pack Curtainless X-Ray System, designed to eliminate traditional X-ray curtains and allow for the inspection of food without contact. The removal of curtains enables lightweight products to undergo X-ray inspection without getting jammed or jostled, reducing the risk of false rejects and delivering higher accuracy and efficiency of inspection. For unpackaged or unsealed dry products, curtain-free inspection eliminates a point of cross-contamination and improves cleanability of the system.

Overhead Door Introduces Hygienic Air Curtain for Cooler Doors to Maintain Temperatures

Overhead Door: +1 800-929-3667

Overhead Door Brand has launched an Air Curtain option for its 991 RapidFlex commercial doors, a solution tailored for cooler applications within the food and beverage industry. Outdated or inadequate sealing doors can strain cooling systems, shortening their lifespan and driving up costs. The 991 RapidFlex doors, now with the Air Curtain option, can minimize the cool air that slips out every time the doors open and close.

The Air Curtain for 991 RapidFlex door is designed to significantly enhance the operational efficiency and cleanliness of facilities, playing a crucial role in preventing contaminants from infiltrating the opening while also effectively drying condensation that may form on the curtain during operation cycles. Overhead Door Brand offers a wide variety of Air Curtain options, including non-heated, heated, washdown, and stainless options.

Hygienically Designed Reject Solution for Food Processors

Eagle Product Inspection contact form

Eagle Product Inspection has introduced its new Short Retracting Nose Reject (Short RNR), a hygienic solution for food processors designed to delicately handle raw product applications. The new reject solution offers a reliable, efficient, and hygienic solution to remove non-conforming product from the line. The Short RNR integrates with Eagle's X-ray inspection machines, powered by SimulTask PRO image analysis software, to eliminate products with bone, metal, and other foreign materials from the line. It effectively handles both bulk and singular applications.

Engineered for demanding processing environments, the Eagle Short RNR features an IP69 rating, making it ideal for thorough and heavy washdown applications. Its hygienic design and open-hinge belt with quick-release feature streamline sanitation and maintenance, minimizing downtime. Designed for high-volume raw applications like poultry and ground beef processing, the Short RNR’s modular structure allows for easy reassembly of single- and dual-lane components, offering flexibility for various production line configurations.

X-Ray Inspection System Series for Larger Packages in Multi-Lane Applications

Mettler-Toledo contact form

Mettler-Toledo's X6 series of X-ray inspection systems for medium- to large-sized packaged products is available in single- and multiple-lane applications. The X6 Series, consisting of the X16 and X36.2 X-ray inspection systems, presents a range of new features that provide precise contamination detection across single or multiple lanes. Both solutions can inspect medium- to large-sized products from 500–600 millimeters (mm) in length, while maximizing productivity through easy-to-use design improvements.

The X16 inspection system is an entry-level X-ray solution for medium- to large-sized products with a HiGain detector, offering high-performance detection of contaminants like metal, glass, stone, bone, and low-density materials across single or multiple lanes. The system can support products up to 300 mm in height, with conveyor speeds up to 60 meters per minute. It also performs additional quality and integrity checks, including product placement monitoring, mass component count, fill level checks, and damaged packaging identification.

For more advanced inspection needs, the X36.2 X-ray inspection system offers high-level detection capabilities for medium to large packaged products. With HiGain+ detector technology and ContamPlus software, the X36.2 offers completeness and integrity checks, identifying small foreign bodies in addition to missing or broken products. The system is highly customizable, with single or multi-lane configurations and numerous reject bin options. It can accommodate high throughputs with speeds of up to 100 meters per minute and the ability to handle over 1,000 products per minute, depending on product size.

Belt Conveyor Enables Smooth Transport of Diverse Goods

Bosch Rexroth contact form

Bosch Rexroth has expanded its VarioFlow conveyor system with the release of the new VarioFlow belt conveyor variant. The belt features a fine-meshed chain surface that is nearly closed and flat, making it suitable for the mass transport of unstable or bulk, film-packed products such as small, sealed-edge bags. At the same time, the VarioFlow belt conveyor can also be used to convey large or wide products, and products that are inherently stable can even protrude sideways in horizontal sections. Unlike conventional chain conveyor systems, VarioFlow modular belts are also suitable for the direct transport of deep-drawn plastic trays, which usually have a delicate contact surface.

VarioFlow includes modular belts in standard widths of 406 and 608 millimeters (mm). Scalable cross-connectors make it possible for integrators to also implement customized belt widths with identical system components. The basic components of the modular belt conveyor system comprise the base unit for the drive, the return unit, the section profile, and vertical and horizontal curves. These allow conveyor lengths of up to 30 meters (m), layouts with curves on both sides, and conveyor speeds of up to 40 m/minute to be realized with one drive. In terms of accessories, VarioFlow plus and VarioFlow belt use identical system components such as product guides, leg sets, and drive kits.