CULTURE

By Lone Jespersen, Ph.D., Founder and Principal, Cultivate SA; Kimberly Crawford, Vice President of Human Resources and Safety, Birchwood Foods; Spir Marinakis, Vice President of Food Safety, Quality, Technical Services, and Sanitation, Maple Leaf Foods; Jessica Morrison, Food Safety Quality Assurance Manager, HACCP Systems, Maple Leaf Foods; and John Boyce, Core Team Member, Cultivate SA and Consultant, Boyce Food Safety Consulting Ltd.

The Connection Between Psychosocial Factors and Food Safety Outcomes

A 2025 Food Safety Summit workshop explored how psychosocial factors are considered in different organizations' food safety systems

Image credit: Robert Shiverts Photography and Food Safety Summit

SCROLL DOWN

On May 13, 2025, at the Food Safety Summit in Rosemont, Illinois, a packed room of attendees participated in the workshop, "Beyond Compliance: Harnessing Psychosocial Factors for a Stronger Food Safety Culture" (Figure 1). In this article, we give a recap of that event and share insights collected from the audience. We also explore how psychosocial factors are considered in different organizations' food safety systems.

The workshop had three objectives:

- Connect food safety culture and psychosocial factors to leading indicators of mature food safety cultures.

- Analyze three companies' challenges and opportunities related to food safety and psychosocial factors.

- Reflect on food safety culture and how to use shared challenges and tactics to go beyond simple compliance and to leverage food safety culture as a competitive advantage.

FIGURE 1. A packed room of attendees at the 2025 Food Safety Summit workshop, "Beyond Compliance: Harnessing Psychosocial Factors for a Stronger Food Safety Culture" (Credit: Robert Shiverts Photography and Food Safety Summit)

Psychosocial factors are the human element of food safety science. As explained in a STOP Foodborne Illness webinar, "Psychosocial factors refer to factors that impact individuals' perception of manager and peer support, personal impact, and control over food safety tasks, to name a few. These factors can impact the retention of critical staff, how front-line leadership supports individuals by listening and encouraging everyone to speak up if they need support, and how individuals are included in problem-solving when there is a food safety issue in their area."1

The workshop was led by Lone Jesperson, Ph.D. of Cultivate SA and supported by Kimberley Crawford of Birchwood Foods and Spir Marinakis of Maple Leaf Foods (Figure 2). The panelists demonstrated practical examples of how psychosocial factors, when properly considered and addressed, support a strong food safety culture and ultimately improve food safety performance.

FIGURE 2. Workshop leaders (left to right) Kim Crawford, Dr. Lone Jespersen, and Spir Marinakis (Credit: Robert Shiverts Photography and Food Safety Summit)

Lone Jespersen, Cultivate SA

Lone began the session by describing four leading indicators of a mature food safety culture:2

- Stability (as indicated by leadership turnover)

- Leadership presence [as indicated by improvement in Good Manufacturing Practices (GMPs)]

- Front-line engagement (as indicated by reductions in the cost of quality)

- Team health (as indicated by awareness and addressing of psychosocial risk factors).

She discussed the links between cultural maturity and psychosocial factors. She also shared how experience with her clients has clearly demonstrated that more mature food safety cultures are associated with:

- A clearer definition of goals and objectives for everyone.

- Increased opportunities for organizing the day.

- A greater likelihood of completing tasks within working hours.

- Greater support from immediate supervisors.

Lone described specific psychosocial factors with a heavy impact on food safety culture, as well as some of the key indicators that can be used to show the impact of these factors, as shown in Table 1.

TABLE 1. Psychosocial Factors and Indicators (Credit: L. Jespersen et al.)

Lone introduced a case study where a company's failure to take these factors into consideration led to an inaccurate hazard analysis and significant lack of control. A dairy company had to recall milk due to cleaning chemicals detected in its products. Using traditional hazard analysis, the risk of chemical residue had been classified as low likelihood and medium severity—and yet, the company ended up having to recall its products. What happened?

The root cause of the incident was determined to be inadequate cleaning of fill nozzles. The fill nozzles were difficult to disassemble and reassemble and required the sanitation team to call maintenance for help. However, a staffing situation compounded the problem. The maintenance manager position for the plant had been open for some time, and the maintenance technician who was called to disassemble the filling machine was new (Figure 3).

FIGURE 3. Impact of psychosocial risk factors on hazard analysis (Credit: L. Jespersen et al.)

There were prevailing norms (i.e., informal rules that influence behavior) from leadership that were found to have impacted the situation:

- An expectation to maximize throughput and uptime to fill customer orders.

- No regular food safety messaging or recognition from leadership.

- Staffing and retention were an operational focus and not a business-critical indicator.

Prevailing norms in both the sanitation and maintenance groups were also found to have an impact:

- "I am clear on goals: Get product out the door."

- "My workload is high, and we run fast every day."

- "My immediate manager is not there for support."

These normative gaps were shown to have directly caused the chemical contamination of the product. There were ongoing vacancies and challenges with retention in critical roles, and it was the local group who had responsibility to manage. There was unbalanced messaging, such that many employees felt that only production numbers really counted. Commercial goals were thus achieved to the detriment of food safety.

In this case study, there were many psychosocial indicators pointing to these potential problems (Table 2).

TABLE 2. Impact of Psychosocial Factors in Dairy Case Study (Credit: L. Jespersen et al.)

Ultimately, when the psychosocial risks were taken into account, it was clear that the likelihood of chemical contamination was high, contrary to the traditional hazard analysis.

“Psychosocial risks—those aspects of a company's culture related to the job environment— can drive food safety decision-making and subsequent actions. For this reason, it is important to consider psychosocial risks in an overall HACCP analysis. These risks should be made part of the HACCP program, on an equal basis with the classical hazard risks (biological, chemical, and physical). Doing so will lead to improvements in the company's overall culture and its ability to decrease overall food safety risks, while leading to a better environment for its employees.”3

Kimberly Crawford, Birchwood Foods

Birchwood Foods, founded in 1936 and based in Kenosha, Wisconsin, is a leading U.S. manufacturer of fresh, frozen, and fully cooked beef and other protein products. With facilities across Wisconsin, Ohio, and Georgia, Birchwood emphasizes food safety, innovation, and sustainability. Still family-led, Birchwood blends tradition with cutting-edge capabilities to serve both foodservice and retail markets nationwide.

Kim Crawford plays a key role in supporting Birchwood's mission of "People working safely to make safe food." Her leadership in the company is defined by a commitment to fostering a culture that puts equal priorities on employee well-being and supporting the success of the business.

Kim's talk centered on the culture roadmap at Birchwood, where the executive leadership team serves as the "cartographers" of that mapping. The team has focused on creating a "shared pool of meaning,"4 the place from which they communicate about the high-stakes topic of food safety. The "shared pool of meaning" refers to the combined set of facts, ideas, feelings, and opinions that people openly share during a conversation. It is the common ground or mutual understanding that forms when people feel safe to contribute their perspectives without fear of judgment or retaliation. The more complete this shared pool is, the better decisions people can make, because they are working with the same relevant information—not just what one person or group believes.

Kim tied these efforts to the mitigation of psychosocial risks, which can come from a lack of organizational objectives and a lack of communication. Kim described a five-year effort to communicate an emphasis on food safety throughout Birchwood, with key, routine messaging from the CEO and the broader executive team.

Birchwood has acknowledged the psychosocial risks associated with job demands and control. There can be an environment where production teams face work overload, demanding machine pacing, and high levels of time pressure. The company's strong, proactive steps to control these risks include recognizing and rewarding employee behaviors that ensure food safety, like the behavior of shutting down a line even when faced with production pressures. These recognition efforts are highly visible and celebrated throughout the company.

Kim talked about the risk of role clarity, particularly with middle management, where there is role conflict and overwhelming responsibility for people. Birchwood looks to task distribution and role clarification to help address these risks.

Kim also described Birchwood's highly successful efforts to help the front line take control of the production process as a mitigation strategy for the psychosocial risk of job control. If not addressed, front-line team members can have low participation in decision-making and lack of control over their workload and pace. Birchwood has addressed this by empowering those front-line employees, giving them opportunity to plan and have influence over their workload. One tool to achieve this has been the multi-disciplinary foreign material eradication teams established at each facility. This team structure gives a prominent voice to front-line team members as part of a food safety and quality assurance (FSQA)/production operations collaboration that is led by management but energized by the contributions of front-line participants.

“When leaders are supported, trusting of each other, communicating openly, and clear in their roles and accountabilities, then food safety outcomes improve.”

Spir Marinakis, Maple Leaf Foods

Maple Leaf Foods is one of Canada's leading packaged protein producers, operating across 19 manufacturing sites in Canada and the U.S. At Maple Leaf Foods, Spir Marinakis is accountable for the strategic direction to deliver on the company's food safety and quality strategy, food safety promise, quality vision, and day-to-day execution of food safety and quality management systems across all sites and laboratories.

Spir shared practical, people-focused solutions across three examples:

- Leadership stability

- People-focused HACCP

- Performance metrics.

Spir discussed how leadership often sets the tone of the food safety culture at a manufacturing site. When leaders are supported, trusting of each other, communicating openly, and clear in their roles and accountabilities, then food safety outcomes improve. On the other hand, when lack of transparency, poor communication, and mistrust occur, the food safety and quality teams may be viewed as "policing," and increased risk should be expected. Spir encouraged training, coaching, and mentoring to build leadership stability, and suggested that when systemic issues occur, teams need to reflect deeply and address psychosocial factors that may be at play.

A HACCP system is effective only when fully understood and implemented by those managing the programs and the front-line teams making the food. Spir discussed how food safety leaders at Maple Leaf Foods benefit from regular communication across sites, and communities of practice, such as the Maple Leaf Foods "8:30 a.m. call," where leaders across all sites connect weekly to discuss best practices and lessons learned. This network of support and information-sharing enables the continuous improvement of dynamic HACCP systems.

Like at Birchwood Foods, HACCP team collaboration has improved by empowering non-FSQA team members to lead or participate in critical projects, such as those related to foreign material or thermal processing. Spir also emphasized the importance of engaging front-line employees, which Maple Leaf Foods achieves through initiatives like "Foreign Material Awareness Month," commemoration activities for the 2008 Maple Leaf Foods outbreak, and partnering with the Alliance to Stop Foodborne Illness.5

Lastly, Spir emphasized that corporate-driven employee performance metrics should be controllable by those being measured. For instance, regulatory non-compliances are included in current metrics, and there was initial debate whether these were always controllable. Over time, however, sites have recognized that by building a positive, proactive relationship with regulatory staff, they have a higher degree of control. Spir also described that while performance targets are determined through a corporate function, the individual sites maintain full autonomy over understanding their site-specific areas of opportunity and developing action plans to improve performance.

Participant Insights

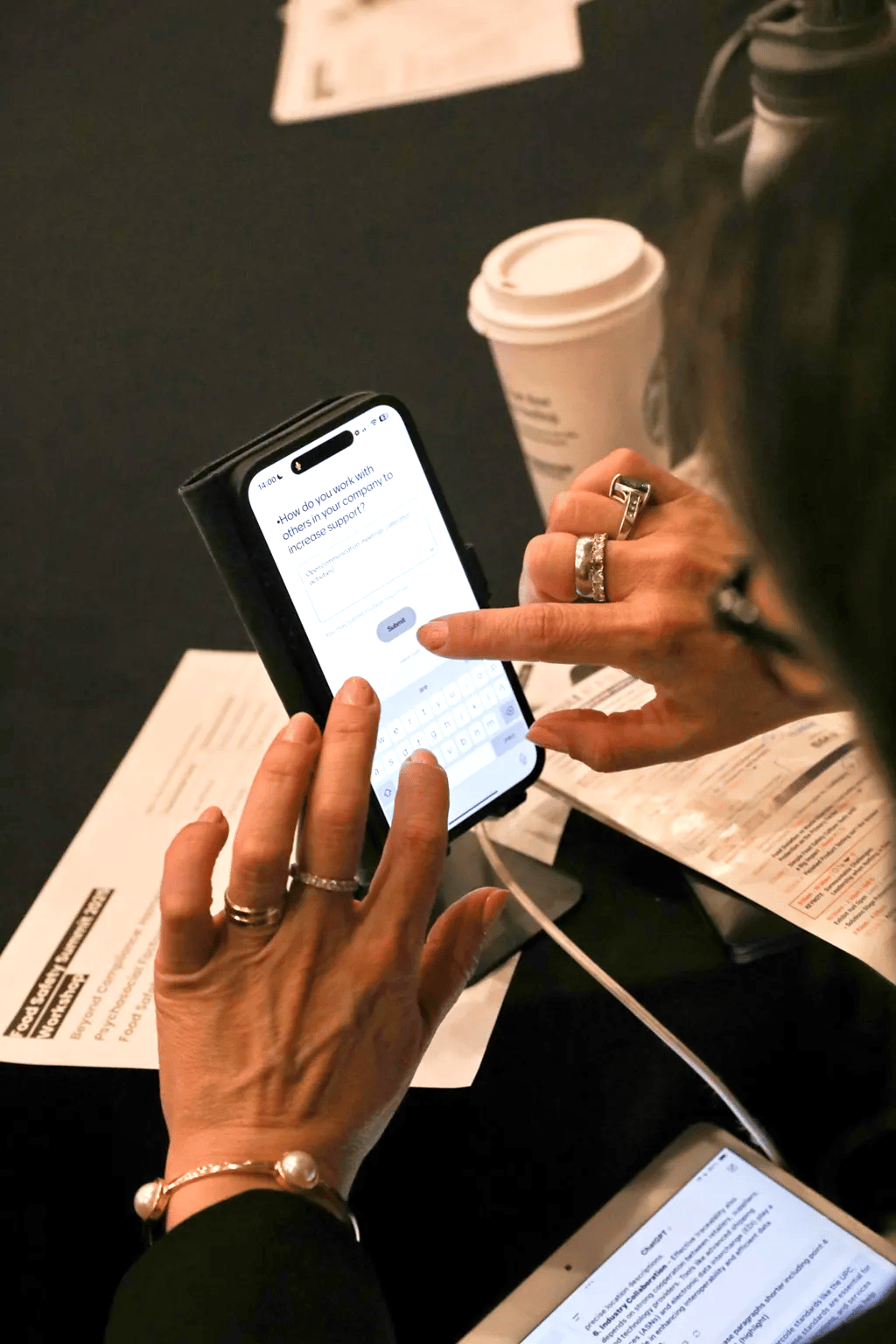

Harnessing the collective wisdom and experience of the large group of attendees was a key component of this workshop. Questions were posed to the group utilizing an interactive audience engagement tool (Figure 4). Below are what the participants had to say about how psychosocial factors are considered in food safety programs at their sites.

Do you consider job demands in your food safety culture efforts?

Eighty-two percent of the respondents answered affirmatively. Lone described this as a "super positive indicator" that the companies represented in this room were managing this psychosocial risk proactively.

Do you consider job control in your food safety culture efforts?

Sixty-one percent answered yes to this question. This might indicate an area in which companies need to do more exploration as to what it means to give people more control over their jobs and their day-to-day responsibilities.

FIGURE 4. Questions were posed to the group utilizing an interactive audience engagement tool (Credit: Robert Shiverts Photography and Food Safety Summit)

Everyone was then asked to collaborate with those sitting at their table on the following three questions. Hundreds of responses were collected. The inputs were broadly characterized by the audience engagement tool as follows below.

What are the strategies in your company to enhance role clarity?

- Prioritize effective communication

- Define clear job descriptions

- Implement clear job descriptions

- Utilize documentation and Standard Operating Procedures (SOPs)

- Conduct regular meetings.

What are your strategies for increasing support?

- Emphasize open communications

- Foster collaboration

- Schedule regular meetings

- Listen and offer help

- Share responsibilities.

What does your company do to connect its food safety culture efforts from leadership to the front line?

- Regular meetings

- Training sessions

- Effective communications

- Rewards and recognition

- Key Performance Indicator (KPI) tracking.

Each of the breakout groups shared some of their specific strategies to address these issues (Figure 5).

FIGURE 5. Breakout groups shared specific strategies to address food safety culture issues (Credit: Robert Shiverts Photography and Food Safety Summit)

Regarding role clarity, one individual described how their company has defined role-specific food safety and quality responsibilities for every employee. They have taken advantage of opportunities to leverage technology to ensure access to information "through the lens of the front-line managers."

Another person described how inclusion of different generational perspectives and varied ethno-religious backgrounds has improved role clarity in their company.

For increasing support, one company has focused efforts to define accountability for middle managers. Each manager is tasked with participation in monthly GMP inspections and expected to help implement change when necessary. "They have to show up. It is tied to their individual KPIs," the attendee explained.

One individual described having spent most of his career in occupational safety. He has transferred key learnings from that discipline into his new role, in which he has key responsibilities for food safety. One such learning is how lagging indicators (e.g., injury statistics) can destroy initiatives for betterment. He gave the example of a company experiencing a recall, and how that recall information can "kill the zeal" for improvement if the individual workers believe the incident was not controllable from their end. He has focused on letting everyone know the role they play and the control they can exert to prevent food safety issues.

Referencing her company's efforts to connect its food safety culture efforts from leadership through to the front line, another participant described her company's initiatives to get leaders speaking to employees routinely, long before there is a recall, a hold, or a breakdown. When an issue does arise, rather than having the senior leadership huddle in isolation to figure out what has happened, they already have the dialogue going. They believe that the answers will be out on the production floor, and experience has shown this to be the case. For this to work, however, leadership must demonstrate its trust in the front-line employees.

The shared wisdom in the room was felt, and the stories offered by representatives from these different companies were fascinating and illuminating (Figure 6).

FIGURE 6. The stories offered by participants during the workshop were illuminating (Credit: Robert Shiverts Photography and Food Safety Summit)

As the workshop drew to a close, Lone reiterated some of the practical solutions that had been highlighted to address psychosocial factors (Table 3).

TABLE 3. Practical Solutions to Address the Psychosocial Factors Discussed in the Workshop (Credit: L. Jespersen et al.)

Three key takeaways were gleaned from this workshop:

- Analysis of processes and systems to identify hazards in food safety management plans must include a serious look at people systems. These systems influence outcomes and food safety maturity.

- Leadership must create a roadmap that is clear and accessible—and walk it every day, bringing every member of the organization along with them.

- Understanding the psychosocial risks experienced by people presents so much possibility when management of those risks is considered. When people have a mutual understanding and feel safe to contribute their perspectives without fear of judgment or retaliation, this results in ownership of food safety by all.

A new food safety culture workshop will be coming to the 2026 Food Safety Summit! To view the agenda and register for the event, which will take place May 11–14, 2026 in Rosemont, Illinois, please visit the Food Safety Summit website. We look forward to seeing you in May!

Acknowledgment

The authors give huge thanks to Bob Lijana, Cultivate SA's Editor-in-Chief, for his editing wizardry. Thanks also to Stacy Atchison, Publisher of Food Safety Magazine, and the Food Safety Summit team for hosting this workshop. We would also like to thank the attendees of this workshop for sharing their collective insights on this topic.

References

- STOP Foodborne Illness. "Webinar 10: Are Food Safety Management Systems Enough?" Conrad Choiniere, Ph.D., Vanessa Coffman, Ph.D., Lone Jespersen, Ph.D., and Lily Yasuda. https://stopfoodborneillness.org/alliance/webinar-series/.

- Jespersen, L., K. Crawford, and S. Marinakis. "Beyond Compliance: Harnessing Psychosocial Factors for a Stronger Food Safety Culture." Food Safety Sumit, May 13, 2025. https://www.food-safety.com/ext/resources/FSS_Event/Presentations/2025/W2---2025_Jespersen.pdf.

- Jespersen, L. and B. Lijana. "Where Food Safety Culture and Systems Collide: Do You Know Your Company's Psychosocial Risks?" Food Safety Magazine April/May 2024. https://www.food-safety.com/articles/9378-where-food-safety-systems-and-culture-collide-do-you-know-your-companys-psychosocial-risks.

- Grenny, J., K. Patterson, R. McMillan, A. Switzler, and E. Gregory. Crucial Conversations: Tools for Talking When Stakes Are High. 3rd Ed. New York: McGraw Hill, October 2021.

- Alliance to Stop Foodborne Illness. "Alliance Members." https://stopfoodborneillness.org/alliance/#:~:text=1%2C124-,ALLIANCE%20MEMBERS,-These%20companies%20commit.

Lone Jespersen, Ph.D. is a published author, speaker, and the Principal and Founder of Cultivate SA, a Swiss-based organization dedicated to helping organizations in the global supply chain make safe, great-tasting food through cultural effectiveness. She has helped improve food safety through organizational culture improvements for 18 years, since her start at Maple Leaf Foods in 2004.

Dr. Jespersen chaired the Global Food Safety Initiative (GFSI) technical working group on food safety culture, the International Association for Food Protection (IAFP) professional development group on food safety culture, and is the technical author on the BSI PAS320 "Practical Guide to Food Safety Culture." She also serves as Vice Chair of the IFPTI board and as a Director on the STOP Foodborne Illness board. Dr. Jespersen holds a Ph.D. in culture enabled food safety from the University of Guelph and a master's degree in mechanical engineering from Syd Dansk University.

Kimberly (Kim) Crawford is Vice President of Human Resources and Safety at Birchwood Foods. She joined Birchwood Foods in 2020 to oversee the company's human resources and safety departments at each facility. Bringing over 20 years of human resources and safety experience to the role, she leads Birchwood's human resources and safety programs, as well as learning and development, to attract and retain the best talent and maintain a safe workplace where every employee has the opportunity to grow and do their best work. Kim co-chairs The Meat Institute's Labor and Employment Committee, and is a member of the national and local Racine/Kenosha (Wisconsin) chapters of the Society for Human Resource Management.

Spir Marinakis is Vice President of Food Safety, Quality, Technical Services, and Sanitation at Maple Leaf Foods, overseeing the processed meats portfolio. Since 2016, Spir has led the strategy and day‑to‑day operation of Food Safety and Quality systems and laboratories, advancing the company's Food Safety Promise and Quality Vision. Spir began her career at Unilever Canada across food science, sales, brand management, innovation, and research and development/quality assurance, earning two Global Innovation Awards. Joining Maple Leaf Foods in 2004, Spir progressed through food safety and quality leadership roles driving Six Sigma initiatives, performance metrics, complaint reduction, and a culture of continuous improvement across North America.

Jessica Morrison is the Food Safety Quality Assurance Manager for HACCP Systems at Maple Leaf Foods. She is responsible for the corporate HACCP/food safety systems guidance (training, coaching, corporate programs maintenance, etc.) to manufacturing sites across Canada and the U.S. She holds an M.S. degree in microbiology from Wilfrid Laurier University.

John Boyce has over 45 years of experience in various aspects of food production, food safety, quality assurance, sanitation, training, and auditing. He spent 25 years with Trident Seafoods, starting as a crab fisherman and then working in roles in plant management, corporate human resources, regulatory compliance, national account sales, food safety, and quality assurance, and then as Director of Training and Development for the company. He spent four years with Diversey, supporting sanitation teams, and eight years with AIB International, conducting food safety audits around the world. John is now an independent food safety consultant based in Vancouver, British Columbia. He enjoys working with clients to help them ensure food-safe products. He is also an expert partner at Cultivate SA for assessing and changing food safety culture in food businesses.