Overhead Cleaning and Inspection Tool for Dust Control

Goodway Technologies contact information

Goodway Technologies has introduced the VAC-DIV2-CAMKIT, a remote, extended-reach, high-resolution inspection camera for overhead cleaning and inspection where dust control is critical, such as in food processing facilities. Overhead areas—such as beams, ductwork, and rafters—collect dust and debris that can pose operational and safety risks. NFPA 660, the new consolidated standard for combustible dust, emphasizes proactive housekeeping and documentation.

SCROLL

DOWN

The VAC-DIV2-CAMKIT solves safety and labor cost challenges by transforming Goodway's carbon fiber extension wands into inspection tools. Key features include:

- The high-resolution camera streams live video and still images to a smartphone

- Extended reach for ground-level inspections eliminates the need for ladders or lifts

- Onboard storage for before-and-after documentation supports internal audits and cleaning verification

- Easy integration with Goodway vacuum systems facilitates seamless cleaning and inspection.

Portable Device for Real-Time Detection of Food Allergens

Allergen Alert contact form

Allergen Alert has introduced the first portable device able to detect the presence of allergens or gluten in a meal with laboratory-grade precision. The pocket-sized "mini laboratory" relies on a patented, single-use pouch derived from bioMérieux's laboratory technologies, which miniaturizes and automates every step of a professional analytical test. Although Allergen Alert was created to meet the needs of people with allergies, its potential extends beyond individual use to the foodservice industry.

Compact and portable, the device enables people with food allergies or celiac disease to test their food autonomously and on the spot, providing a preventive solution to a major public health challenge. The lightweight, battery-powered device analyzes a calibrated, representative food sample placed inside a single-use pouch. Within minutes, the result clearly indicates whether an allergen or gluten is present. bioMérieux researchers developed Allergen Alert's core miniaturized technology: a sealed, single-use pouch that automates the entire analytical process (i.e., sample preparation, protein extraction, migration, detection, and analysis). By making laboratory-grade detection available onsite in minutes, Allergen Alert offers a new solution for food safety control.

Clean-Label Processing Aid for Listeria

Innodal contact information

The U.S. Department of Agriculture's Food Safety and Inspection Service (USDA-FSIS) has issued a No Objection Letter (NOL) for Innodal's INNEO as a processing aid to control Listeria monocytogenes in meat and poultry products. This NOL enables U.S. meat and poultry processors to use INNEO both as a surface treatment and directly within the food matrix of comminuted products. INNEO is a natural antimicrobial processing aid based on a bacteriocin, a class of peptides recognized for their targeted activity against L. monocytogenes. The technology is also determined "Generally Recognized as Safe" (GRAS) by the U.S. Food and Drug Administration (FDA).

Already commercialized in Canada, INNEO offers U.S. processors a clean-label alternative to conventional antimicrobials. Industry trials have demonstrated strong efficacy against L. monocytogenes while preserving product quality attributes such as taste, texture, and appearance. As a recognized processing aid, INNEO can be implemented without ingredient labeling changes.

Compostable, No-PFAS-Added Pulp Packaging for Foodservice

Sabert Corporation Europe contact form

Sabert Corporation Europe has launched a line of fully home compostable and recyclable foodservice packaging. Made from renewable, plant-based resources, the range is free from intentionally added per- and polyfluoroalkyl substances (PFAS) and compliant with forthcoming EU sustainability regulations. The new ranges have been developed and validated over time to ensure safety and performance in demanding foodservice and retail environments.

To align with new EU regulatory requirements regarding food packaging, Sabert has evolved its entire pulp portfolio into the HC (home compostable) range. Building on this foundation, Sabert introduced Pulp Ultra, a next-generation, no-intentionally-added-PFAS formulation that meets both legislative standards and customers' expectations for strength and heat resistance. Together, the HC and Pulp Ultra ranges give customers a choice between a standard home-compostable option and an ultra-high-performance solution, both of which meet Sabert's quality standards.

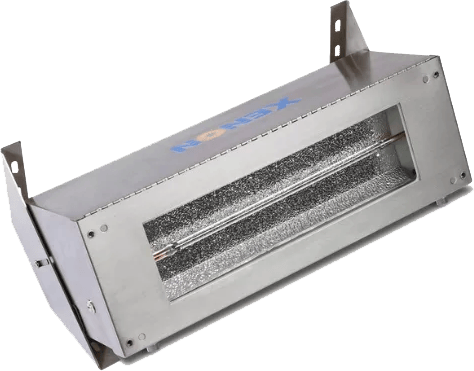

Pulsed Light System for Pathogen Control

XENON Corporation contact information

XENON Corporation has introduced the Compact Integrated Xenon Lamp (CIXL), a fully integrated, plug-and-play system designed to deliver high-energy pulsed light for food safety and shelf life improvement. The technology provides processors with a non-chemical solution for pathogen control while preserving product quality. Pulsed light technology has gained industry acceptance for applications such as packaging sanitization, including yogurt cups, and continues to expand into broader food processing uses.

The CIXL system incorporates XENON's PurePulse Technology, an FDA-approved method for food processing that uses high-intensity pulsed light to sanitize surfaces in production environments. This approach helps reduce contamination risks on walls, ceilings, racks, packaging surfaces, and other areas where microorganisms can thrive. At the core of the CIXL is an 11-inch xenon arc lamp paired with a diffuse reflector, integrated electronics, and a cooling system. The configuration generates 3 hertz (Hz) pulses at 505 joules each—equivalent to 100,000 times the intensity of sunlight at Earth's surface. All components are housed in a brushed stainless-steel enclosure with a quartz window for durability in industrial settings.

Time-Temperature Monitoring Label for Food Products

Vitsab International contact information

Vitsab International AB has introduced Freshtag, a color-changing smart label designed to monitor perishable foods for time and temperature, ensuring food safety and quality. Freshtag is based on Stoplight Technology, which provides a clear, universally understood visual cue; labels remain green under safe conditions, then shift to yellow, and finally, to red if temperature abuse is detected, according to specific product guidelines. The simple visual progression allows all users across the supply chain, such as foodservice employees and consumers, to quickly validate food safety at a glance.

Freshtags are compliant with FDA, EU, HACCP, and ISO9001 standards. The Freshtag system is suitable for use in refrigerated, frozen, or passive storage environments. With no tools or technical setup required, labels are simple to receive, store, and apply in diverse situations, such as campus dining, remote services, retail settings, e-commerce packaging, or home delivery.

Easy-Access Reject Device for Gravity Metal Detectors

Fortress Technology contact information

Accessing a gravity metal detector's reject device and removing it from service for deep cleans and maintenance can be difficult when the reject mechanism is enclosed. To address some of the most common issues encountered in gravity metal detection, Fortress Technology has designed a roll-out reject device to support faster changeovers and better hygiene.

The new design allows the reject valve to roll out on rails, providing quick and easy access to the product flow area inside the valve and product tube. This feature gives operatives complete access to working parts for maintenance and cleaning once correctly locked out, ensuring optimal hygiene conditions for gravity reject devices. Unlike other reject devices, such as clean-out doors, the valve's body rigidity is not compromised.

Optical Sorter for Foreign Material in Leafy Greens

Key Technology contact information

Key Technology has launched its COMPASS optical sorter, designed specifically for fresh-cut leafy greens. The belt-fed system combines high-performance foreign material (FM) detection and removal with gentle, hygienic product handling to help processors enhance food safety and operational efficiency. Engineered for early-stage processing, COMPASS inspects product straight from the field and removes a wide range of physical contaminants—including dirt clods, rocks, sticks, insects, and animal parts—as well as product defects when sorting single varieties. The system is ideal for spinach, arugula, and other unwashed leafy greens, including salad mixes.

COMPASS offers customizable camera configurations with up to eight channels of multispectral sensor data. When equipped with Key's Pixel Fusion technology, the sorter combines visible, infrared, and shortwave infrared data at the pixel level for enhanced FM and defect detection. An optional chlorophyll-sensitive channel further improves contrast between greens and contaminants. The system addresses challenges associated with handling lightweight, moist leafy greens by integrating optimized infeed conveyors and optional air-assist systems for smooth product flow. Air knives at discharge help prevent good product from sticking or falling short.

Designed for sanitation and ease of maintenance, COMPASS features an open frame, sloped surfaces, and quick-release belt removal for fast washdowns. A clean-in-place system with spray bars and brushes maintains hygiene during production, while high-mounted camera windows and a dry-air boost system protect sensors in humid or refrigerated environments. The sorter's open architecture provides visibility into the product zone and accommodates integration with downstream equipment. For processors upgrading from Key's legacy Optyx sorter, COMPASS shares the same footprint for seamless installation.

X-Ray Series for Bulk Foods Inspection

Mettler-Toledo contact information

Mettler-Toledo Product Inspection Group has introduced the X3 Series of bulk flow X-ray inspection systems for physical contamination detection, enhanced with waste reduction and simplified operational features. The X3 Series has been developed specifically for unpackaged, loose-flow, bulk products on conveyors. Both systems in the series can detect contaminants as small as 0.3–0.4 millimeters (mm), depending on application and contaminant material. Typical applications include dried, fresh, or frozen fruits and vegetables, nuts, pulses, root vegetables such as carrots and potatoes, confectionery, and cereals.

Reject options include a 30-nozzle air blast for pinpoint removal of contaminants in smaller products, or a six-flap pusher reject for the removal of contamination in larger produce. With reject devices positioned above the product, they are less likely to become blocked or clogged with product debris, thereby maintaining performance and supporting hygienic handling. These targeted reject systems are intended to help manufacturers minimize product waste and protect profitability. X3 Series features throughput rates of up to 5,000 kilogram (kg) per hour.

As the X3 Series' premium offering, the X53 is engineered for manufacturers who handle the most complex bulk products and require precise accuracy. By processing two energy spectrums simultaneously, the X53 can differentiate between materials with similar densities such as bone and product, allowing it to detect challenging low-density contaminants that single-energy systems may miss. The X53 also introduces traceability and automation features, including product validation routines, self-checking performance verification, and a fully lockable inspection tunnel for secure operation. These capabilities make it suitable for high-throughput or high-risk environments, where sensitivity, reliability, and compliance are critical.

Both X3 models feature front open conveyor access and tool-free removal of key components. Options such as belt scrapers, water-cleaning systems, and removable guide rails increase sanitation speed and effectiveness, while integrated cable management reduces clutter. Each system is available with a choice of ingress protection ratings up to IP69, providing flexibility to suit different hygiene standards and cleaning regimes.

New and Improved Pipeline X-Ray System

Eagle Product Inspection contact

Eagle Product Inspection recently unveiled its redesigned Pipeline X-Ray System for pumped products, offering improved machine construction and built-in inspection technologies. Pipelines uses advanced PXT photon-counting dual energy X-ray technology for bone and foreign metal detection in poultry, meat, pet food, and other pumped products, with the ability to reject items before packaging or further processing with a lower false reject rate. The system offers flexible configurations and has unique features, such as a flowmeter with variable speed functionality, test ball insertion port, and reject catch port. Additionally, users can choose from multiple detection options, including single, dual, and photon-counting PXT technologies. Pipeline's construction also withstands harsh washdown conditions and has been refined to comply with North American Meat Institute (NAMI) guidelines for hygiene and sanitation. The system also fully aligns with the meat and poultry industry's Directives, Regulations, Norms, and Standards (DRNS).