PCR-Based Salmonella Detection Kit

Bio-Rad Laboratories contact form

Bio-Rad Laboratories has launched the EZ-Check Salmonella Kit—a rapid, polymerase chain reaction (PCR)-based solution for the qualitative detection of Salmonella in a wide range of food and environmental matrices. The kit has received validation from AOAC International under the Performance Tested Methods program and NF VALIDATION certification from AFNOR Certification. It features a ready-to-use format with multiplex amplification of the target pathogen and an internal control to mitigate false negatives. Its duplex detection system enhances result accuracy while simplifying assay setup, supporting streamlined workflows in food safety laboratories.

SCROLL

DOWN

New Testing and Monitoring Solutions from NEMIS

NEMIS Technologies contact form

For "on-the-go" hygiene monitoring, NEMIS Technologies has introduced ATP GO and ATP GO Liquid. ATP GO is a portable, rapid, and sensitive method for hygiene monitoring of surfaces and equipment in food production and processing environments. The test measures adenosine triphosphate (ATP), a key indicator of contamination from microbes or food residues. Similarly, ATP GO Liquid is designed for testing liquid samples in food and beverage facilities, including process water, clean-in-place (CIP) rinse water, condensation, cooling systems, and even bottled or stored water.

Another innovation from NEMIS Technologies, NEMIS iNactivate, is a device that uses a patented, multi-sided heating technology to fully inactivate any non-spore forming microorganisms enriched in NEMIS N-Light test tubes. The device allows for safe disposal of N-Light test tubes by eliminating the risk of live pathogen handling and ensures compliance with biohazard regulations, reducing the need for specialized waste handling. iNactivate runs on fully automated 30-minute cycles at 85 °C, and features a colored LED signal for cycle completion.

Hygienically Designed X-Ray System Offers Audit-Ready Product Inspection

Eagle Product Inspection contact form

Engineered for harsh washdown environments, the Eagle Pack 400 HC with PXT X-ray system offers dual energy technology, superior contaminant detection, and inline quality checks—all in a hygienic, easy-to-clean system that helps food processors stay audit-ready. Ideal for meat, poultry, seafood, and dairy processors, the Pack 400 HC is hygienically designed to NAMI standards and meets IP69 ingress protection specifications. Additionally, the advanced PXT detector uses photon-counting dual energy technology to find small contaminants and bone fragments, which are often missed by conventional X-ray systems. Beyond contaminant detection, the Pack 400 HC with PXT performs simultaneous inline product integrity checks to verify mass, count components, identify missing or broken items, and detect unwanted voids.

Testing Solution for Heat-Resistant Molds Available in U.S.

bioMérieux contact form

bioMérieux has launched its GENE-UP® PRO HRM testing solution for viable heat-resistant molds (HRMs). GENE-UP PRO HRM is the only DNA-based testing solution on the market for the detection of viable heat-resistant molds (HRMs), including those in the ascospore state. The innovation reduces time to results to three days from 15 days, helping to improve operational efficiencies and profitability through quicker product release, increased shelf life, and reduced storage costs. GENE-UP PRO HRM also has validated equivalence to CMMEF Ch22 Reference Method. The product is now commercially available in the U.S.

Comprehensive Drain Upgrade Program for Food Facilities

FoodSafe Drains contact form

FoodSafe Drains has launched Renew Services, a comprehensive program dedicated to replacement, upgrade, and improvement solutions for drainage systems within the food and beverage industry. Foodborne illness outbreaks can frequently be traced back to pathogenic contamination originating from failing drain systems in food production facilities. When drainage systems are neglected or outdated, they can quickly become sources of unsanitary conditions and contamination throughout the facility. Poor drainage can also cause unpleasant odors, slippery floors, and even structural damage, all of which compromise both food safety and worker health.

Addressing these issues proactively is essential for maintaining a safe, compliant, and efficient production environment. Renew Services reflects FoodSafe Drains' deep understanding of the unique challenges faced by food and beverage facilities when it comes to maintaining, upgrading, or replacing critical drainage systems. The program leverages FoodSafe Drains' alliance partner network of installers, ensuring expert installation and support for every project. A key advantage of Renew Services is its focus on minimizing operational disruption. The program is structured to mitigate risks by providing quick shipping and limiting downtime, helping facilities maintain productivity and compliance with industry standards.

Online Training Academy for UK Food Safety Professionals

LOMA SYSTEMS: +1 800-872-5662

LOMA SYSTEMS contact form

LOMA SYSTEMS has officially launched its LOMA Online Training Academy in the UK. The online initiative provides customers with a smart and sustainable way to train their teams, allowing businesses to upskill staff, while ensuring compliance and optimizing the performance of their inspection systems. The online academy offers a wide selection of operator, supervisor, and quality assurance courses, developed by LOMA's in-house specialists to provide practical knowledge and certifications. To flexibly train employees at a convenient time, pace, and location that best meets their operational needs, the academy is available 24 hours a day, seven days a week, and can be accessed via smartphone, tablet, laptop, or computer.

Loma customers can explore the comprehensive online course catalogue, which includes key inspection technologies such as metal detection, X-ray inspection, and checkweighing, as well as broader training to support food safety and quality management. Each course is delivered through engaging modules featuring videos, knowledge checks, and supporting documentation. Upon completion, learners can download certificates, providing evidence of competence and compliance. To offer businesses a risk-free way to explore the platform, the online academy also provides free introductory courses designed to highlight the advantages of online learning.

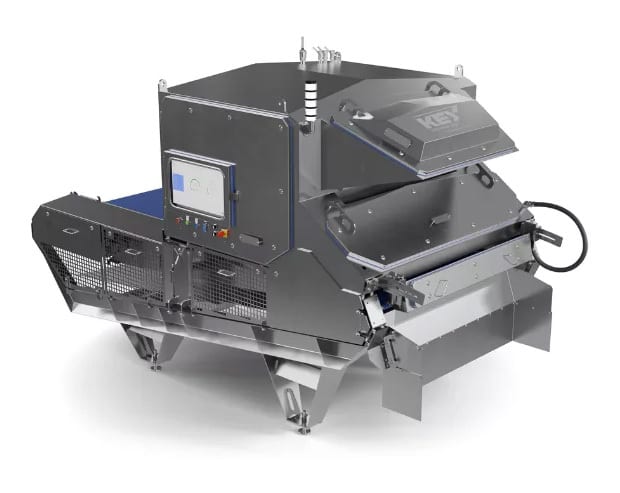

Belt-Fed Optical Sorters Ideal for Wet, Sticky, Delicate Foods

Key Technology: +1 509-529-2161

Key Technology contact form

Designed for wet, sticky, and delicate products, Key Technology's COMPASS belt-fed optical sorter helps processors ensure food safety, achieve precise product quality, and maximize yield while delivering a compelling return on investment. The belt-fed COMPASS is ideal for a variety of produce, snack foods, and other products that cannot be handled by chute-fed sorters. The belt configuration provides gentle handling for delicate applications, reducing product breakage while maintaining high throughput.

Powered by Key's advanced NEXT sort engine, COMPASS finds and rejects plastic, glass, paper, wood, and other organic and inorganic foreign material, as well as processor-specified product defects. The belt can be quickly removed for thorough cleaning, while the open design facilitates easy access for workers and minimizes cleaning and maintenance requirements. COMPASS is available in a range of configurations and sizes to meet individual customer application and capacity requirements, and the system can be installed at a variety of points in the processing line.

Fully Autonomous Mobile Pallet for Multi-Facility Logistics

Logic Robotics contact form

Logic Robotics has unveiled the Logic Pallet, a first-of-its-kind multi-facility mobile robot engineered to automate and unify end-to-end movement of goods between and within facilities. Currently in production and made in the U.S., the 48-inch (in.) by 40 in. Logic Pallet is purpose-built to handle boxed consumer goods and food, replacing traditional pallets and forklifts entirely. With a robust payload capacity of 2,000 pounds (lbs.) or 907 kilograms (kg), 160-hour battery life, and autonomous functionality from origin point to vehicle transloading, it empowers logistics operators with an unmatched level of automation, safety, and throughput.

The Logic Pallet is a self-driving, self-loading, and self-unloading robotic platform. It functions as an in-facility shuttle for various standard-sized pallets, supporting automated movement to storage, pick, and retrieval positions, maximizing both warehouse density and operator productivity. Designed for versatility, the Logic Pallet supports high-density, aisleless storage in order to deliver up to three times the storage capacity of traditional warehouse configurations. With autonomous stacking, return for reuse, and advanced self-navigation capabilities, the Logic Pallet dramatically reduces operational downtime, labor dependency, and waste. It also features a patented, weight-based inventory management system for on-demand cycle counting, along with automated item recognition to provide real-time inventory insight, reducing manual labor and eliminating costly errors.

New and Improved Pipeline X-Ray System

Eagle Product Inspection contact

Eagle Product Inspection recently unveiled its redesigned Pipeline X-Ray System for pumped products, offering improved machine construction and built-in inspection technologies. Pipelines uses advanced PXT photon-counting dual energy X-ray technology for bone and foreign metal detection in poultry, meat, pet food, and other pumped products, with the ability to reject items before packaging or further processing with a lower false reject rate. The system offers flexible configurations and has unique features, such as a flowmeter with variable speed functionality, test ball insertion port, and reject catch port. Additionally, users can choose from multiple detection options, including single, dual, and photon-counting PXT technologies. Pipeline's construction also withstands harsh washdown conditions and has been refined to comply with North American Meat Institute (NAMI) guidelines for hygiene and sanitation. The system also fully aligns with the meat and poultry industry's Directives, Regulations, Norms, and Standards (DRNS).